- Testador de abrasão Suga, reproduzindo configurações de abrasão deslizante;

- Máquina de abrasão para abrasão por deslizamento de materiais poliméricos (DIN 53.516, ASTM D5963 e BS ISO 4649);

- Máquina de abrasão de roda de borracha de areia seca (ASTM G65);

- Resistência à abrasão de alta tensão de materiais duros (ASTM B611);

- Máquina de abrasão para abrasão de rolamento (desgaste abrasivo de três corpos).

- Deslizamento alternado para ensaios em capa externa de mangueiras hidráulicas (ISO 6945:2001)

Facilities

We are equipped with a modern infrastructure to reproduce tribological systems that are found in industrial applications. We also have facilities for corrosion-erosion testing, friction welding processes (Friction tapered plug welding) and depth-sensing indentation. This infrastructure was developed through partnerships with the private sector and by developing R&D projects with the support of government agencies.

Following, some of our research facilities are listed. If any special field test conditions are required, we offer the possibility of developing and constructing new facilities to fulfill your demands. Do not hesitate to contact us.

- Microindentation and microscratch tester (ASTM G171);

- Scratch testing instrument for hard coatings equipped with acoustic emission sensor (ASTM C 1624 and D 7027).

- Pin-on-disc apparatus (ASTM 99);

- Bloc-on-ring wear test (ASTM G77);

- Reciprocating pin-on-flat sliding tester (ASTM 133);

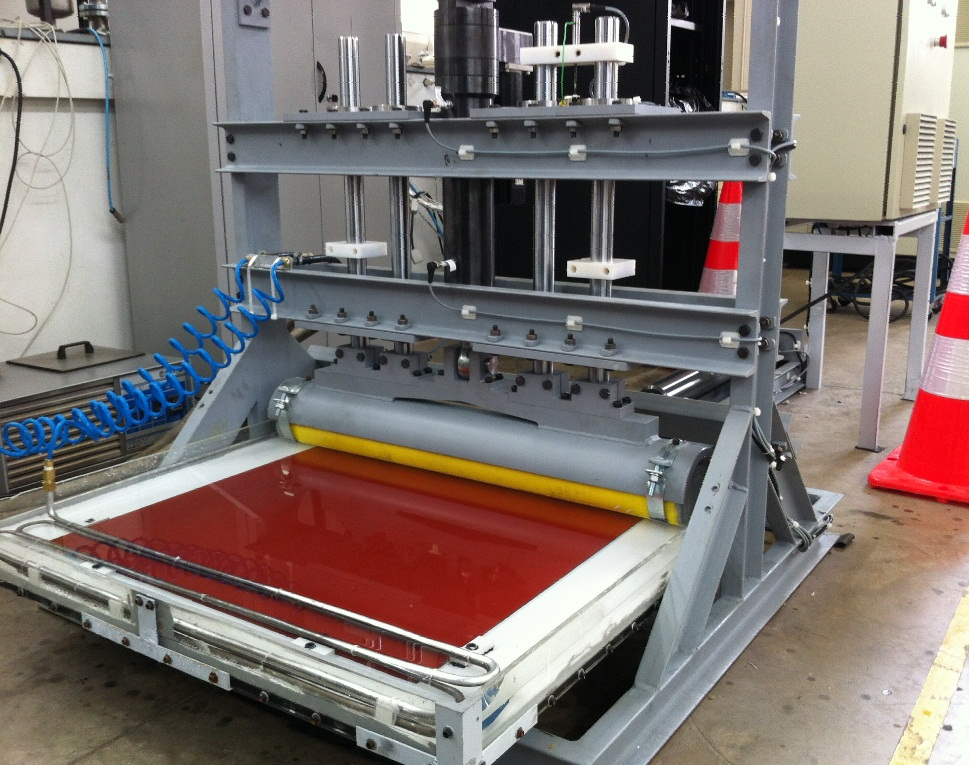

- Large-scale tribometer for reciprocating sliding of umbilicals;

- Large-scale tribometer for reciprocating sliding of flexible riser pipes.

Large-scale tribometer for reciprocating sliding of umbilicals.

Large-scale tribometer for reciprocating sliding of flexible riser pipes of up to nine inches

- Instrumented macroindentation testing;

- Instrumented microindentation testing (ASTM E 2546);

- Instrumented Indentation Testing (ISO 14577 e ASTM E2546);

- Vickers hardness (ASTM E384);

- Brinell hardness (ASTM E 10);

- Rockwell hardness (ASTM E 18);

- Shore A and D hardness;

- Pull-off strength of coatings using portable adhesion tester (ASTM D4541/D7234, ISO 4624/16276-1, AS / NZS 1580.408.5);

- Tension testing of metallic materials (ASTM E8/E8M);

- Miniaturized charpy impact test (ISO 14556:2015, ASTM E2248-18 e ASTM E2298-19);

- Linear-elastic plane-strain fracture Toughness KIc of metallic materials (ASTM E399).

- Liquid jet impingement erosion testing;

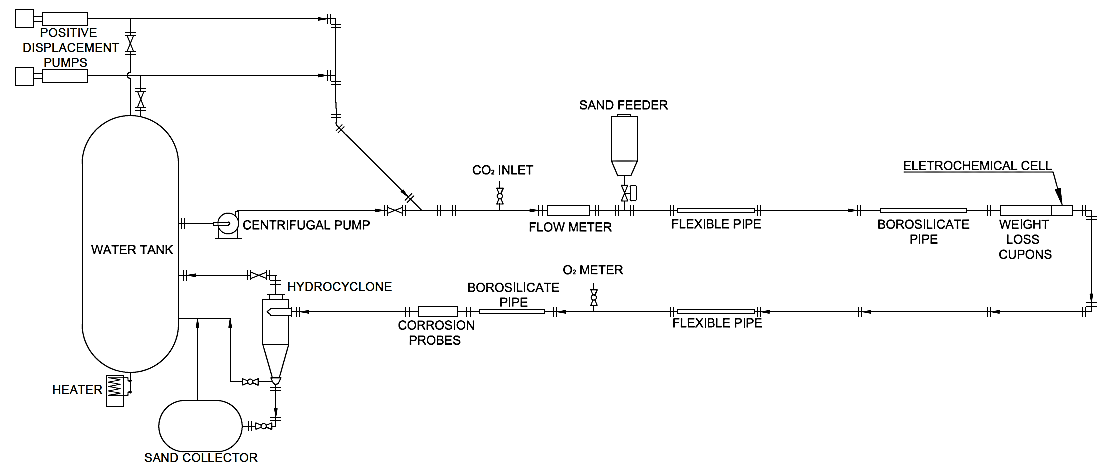

- Corrosion-erosion testing using a four inch flow loop;

- Corrosion inhibitor efficiency tests with sand particles in the flow stream;

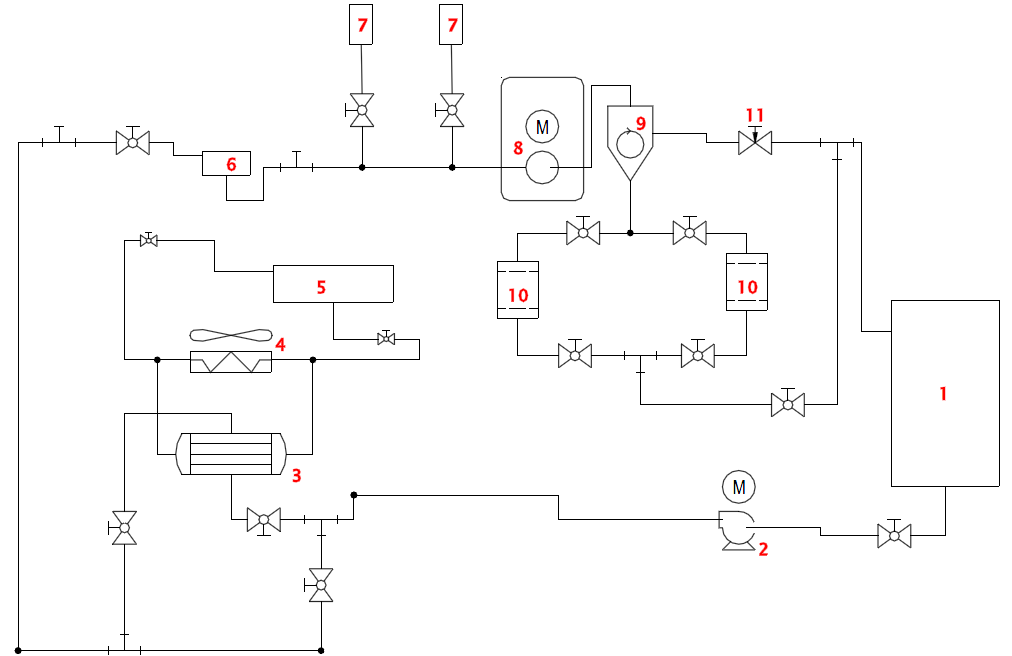

- Testing equipment to verify the performance of electrical submersible pumps (ESPs);

- Salt spray corrosion testing (ISO-9227 / ASTM-B-117 / ABNT-NBR-8094 / DIN-50021);

- Hydrogen Embrittlement according to the following standards: G129, ASTM E 1681, F1624, F1624, ISO 16573.

Four inch stainless steel flow loop for testing corrosion-erosion

Flow loop for testing electrical submersible pumps in respect to their performance when pumping liquid with sand

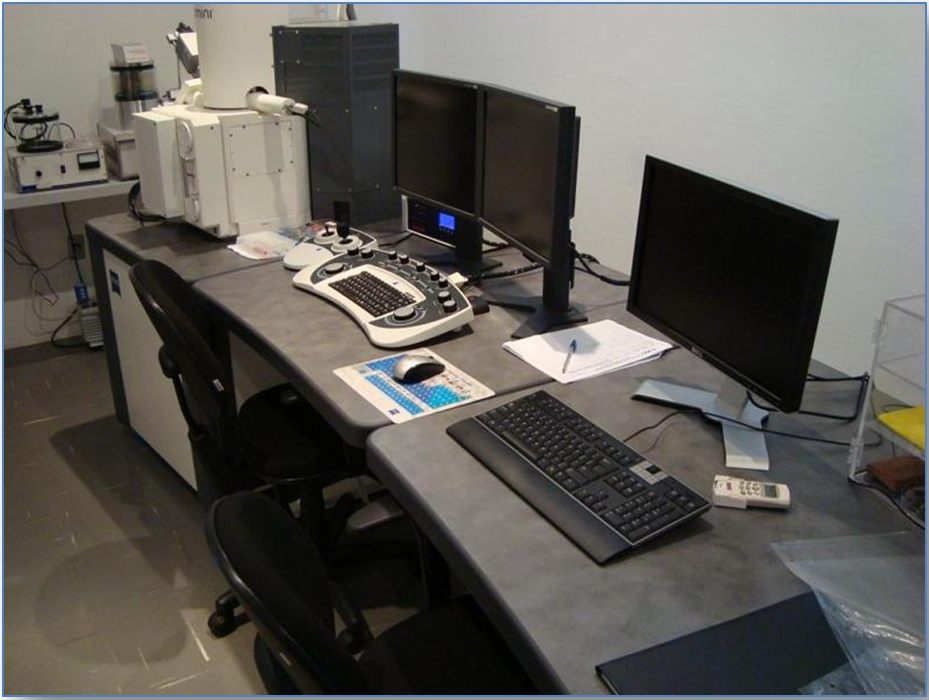

- Complete infrastructure for metallographic sample preparation and analysis including optical and scanning electron microscope (ASTM A247, E 45, E 112, E 1245, E 1382, E 1503, E 2142).

High resolution scanning electron microscope (FEG), equipped with EDS detector

- Friction coefficient using inclined plane (TAPPI T-815);

- Chemical composition using glow discharge optical emission spectroscopy;

- Chemical composition using Energy-Dispersive X-Ray Spectroscopy (EDS);

- Determination of diffusible hydrogen;

- Surface topography measurement using CLA, laser and inductive gauges.

Mechanical parts may fail due to many reasons. In the LFWT we are equipped with the necessary infrastructure to investigate failure origin in different mechanical parts.